Getting Started

Login, Modules Overview, and Access

Analytics Overview

Support Options

Billing Module

Flourish Supported Hardware, Networking, and Vendors

Edit Your Flourish Software User Profile

Submit a New Idea to Flourish Software

Configuration & Setup

Company Settings

Editing Your Company Profile

Automatically Lock Packages Based on Test Result Status

Upload Your Company Logo

Retail Return Reason Codes

Inventory - Extended Item Price (EIP)

Facility Settings

Facility Tag Settings

Manage Facility Payment Methods

Facility Compliance Screen

Update Facility and Invoice Origin Address

Update License Number

Update Phone Number

Configure and Manage a Reverse Sync User

Facility Area and Location Management

Configurations per Facility

Labels & Printing

Flourish Label Maker - Configure Labels

Printer and hardware options and setup

QZ Tray Certificate renewal

Allowing Local Network Access for QZ Tray

Example Guide: Subnetting a Router for 250 Local IP Addresses with Static IP Assignments

Printer Setup and Connectivity Guide

Flourish Software Cannabinoid and Terpene List

Flourish COA Portal QR Code - Arizona Requirements

Installing a Unicode-Supported Font on Zebra Printers

Labeling Guide for Dose Based Items (Capsules, Drinks, Edibles, Tinctures, etc.)

Distribution

Distribution Setup

Managing Destinations

Create and Update Destinations In Bulk

Managing Sales Reps

Assign Sales Reps to a Destination

Add/Create Vendors

Create And Update Vendors In Bulk

How to Tag Drivers

Create and Manage Vehicles

Create And Manage Drivers

Users & Permissions

User Roles and Facility Permissions

Creating and Managing Users

Setting Up Users for Mobile Access

How to enable "Update financial info for shipped orders"

Enable Add a New Physician to User Roles

Resetting Your Password in Flourish

Reset User PIN (Point of Sale or Mobile)

Retail POS - Allow to Allocate Inventory to a Purchase Order Manually

Flourish Compliance Credential Guides

Prevent Users from Exporting All Grid Data

Manufacturing Machine & Run Configuration

Item Pricing - Update Multiple Item Prices

Create and Update Strains in Bulk

Enable the creation of new items from the Inventory Screens

Update Items in bulk

Create and Manage Shifts

Cultivation

Grow / Cultivation Overview

Entering in Dry Weights

Overview: Plant Groups and Plant Batches

Change Strain on a Plant

How to split a group

Changing the UOM of a Harvest's Wet Weight

Creating "Fresh Frozen" packages - all you need to know

How to Bulk Destroy Plant IDs

Adjust Expected Harvest Date

Splitting Immature Plant Groups

Non-METRC Creating a Package of Clones

How to create strains

How to Move Plants

How to Create Clones From a Mother Group

Entering in Wet Weights by Group (non-METRC)

METRC Harvest: Record Wet Weight with Scale and Scanner

Cultivation Area Attributes

How to Manicure a Harvest

Creating New Strains

Entering in Dry Weights and Creating Packages from Harvest

How to Apply Additives to Plants

How to Kill plants

Recording Waste for Harvests (METRC)

Destroying Plants: Logging Waste / Notes

Cultivation - How to Revive Plants (No Tracking System)

Creating Plants in Flourish Software

Move harvested strains back to the Flowering phase

Record METRC Harvest with Total Wet Weight

Reprint Plant Tags

Making "Fresh Frozen" products from a Harvest in the "Processing" stage.

Non-METRC - Move a harvest back from 'Processing' to the 'Harvest' phase

How to Kill Individual Plant IDs

How to Make a Mother Group

Kill Individual Plant IDs from Plant Groups

NON-METRC - How to Make a Clone

Harvest packages and Configuration

Making "Fresh Frozen" products from wet weights.

Canada - Destroy plants

METRC Harvesting - wet and dry weights, waste, harvest packages and completion.

Complete and Uncomplete a Harvest

Creating a Package from Harvest

Record Cultivation Waste (Pre-Harvest)

Flourish Software Harvesting

Flourish Analytics

Flourish Analytics - Getting Started

Flourish Analytics - Set User Access and Access Level

Flourish Analytics - Browse Content

Flourish Analytics - Set a Workbook as Favorite

Flourish Analytics - Customize and Bookmark the Data

Flourish Analytics - Export Data

Flourish Software messages and notifications

NewYork Microbusiness Tax Filing SOP

Flourish Software Snowflake Marketplace Data Listing

Android Mobile App

Mobile App: General

Flourish Android Mobile App Overview

Mobile App Login

Mobile User Roles

Mobile Scanning Devices

Mobile Zebra Scanners - connect to Flourish Software app - DataWedge App Setup

Android App Mobile Settings: Choose Package ID to Display

Mobile App: Cultivation

Mobile App - Using a scanner for Cultivation Actions

Mobile App - Harvest - Scan and Record Weights for Plants

Mobile App: Inventory

Mobile App Inventory: Assign a Package to an Order

Mobile App Inventory: Update Lot Number for Non-Cannabis Inventory

Mobile App Inventory: Locate Non-Cannabis

Mobile App Inventory: Take Lab Sample

Mobile App Inventory: Create a New Package

Mobile App Inventory: Lock Package

Mobile App - BioTrack 2.0 - Creating Lab Samples

Mobile App Inventory: Adjust Package

Mobile App Inventory: Adjust Non-Cannabis Inventory

Mobile App Inventory: Locate Package

Mobile App: Inventory Counts

Mobile Inventory Counts Overview

Mobile Inventory Count - Enter the Number of Packages per Item

Mobile Inventory Counts: Scan Packages per Item

Mobile App: Outbound

Mobile App: Shipments

Android mobile - Allocate non-cannabis inventory

Mobile Order Line Screen

Mobile App: Build Orders by Scanning and Allocating Packages

Mobile App: Retail

eCommerce

Jane Technologies

Flourish WooCommerce

Setting up WordPress Site, WooCommerce, and Plugins

Flourish WooCommerce Wholesale Configuration Guide

WooCommerce Wholesale Store Branding and Client Experience Guide

Managing Multi Accounts and Sub Accounts in WooCommerce

Flourish Wholesale Portal User Guide for Buyers

Order Sync Workflow - WooCommerce to Flourish Application

Inbound

Inbound Module Overview

Inbound Purchase Orders

Inbound - Display Additional fields next to item names on purchase order lines

Tutorial: Create Purchase Order

Receive Inbound Transfers and Purchase Orders (No Compliance System)

Inbound - Receive The Whole Purchase Order In One Click

Quick Receive Non-Cannabis Inventory

Moisture Tracking

METRC Inbound Process

Inventory

Bulk Actions

Bulk Actions - Add Packages to an Order

Bulk Actions - Combine Packages

Bulk Actions - Locate Packages

Bulk Actions - Lock and Unlock Packages

Bulk Actions - Add to a Manufacturing Run

Bulk Actions - Print Package Labels

Bulk actions - Update Unit weight

Create Items in Bulk

Inventory Counts

Inventory Settings

Item Creation & Management

Package Unit Cost Inheritance and Calculation

Creating a Custom Category

Manage Item Ecommerce Names

Add Ingredients to Items and print in outbound PDF

Inventory Management Principles

Classes & Categories

Clone an Existing Item or BOM

Duplicate an Item to Create a New Item

Lock Codes, Adjustment Codes, & Return Reasons

External and Internal Items

Item Tagging Functionality

Chart of Account Mapping

Configuring Item E-Commerce Categories and Subcategories

Item Strain Type

Change an Item Category

Item Vendor UOM Conversion

Inventory Management

Custom Grid Column Ordering

Brand Management

Web Inventory Counts: Enter the Number of Packages per Item

Print Labels For Non-Cannabis Items

Tutorial: Creating an Item

Create Package from Package

Inventory Adjustments

Create And Manage Custom Views

Managing Inventory Lock Codes

Managing Chart of Accounts View - QuickBooks Online

Package History

Create Lab Samples when a Lab Test Batch "Required Testing" (LTB Option) is required.

Create multiple packages with different quantities in one session.

Update The Unit Weight for a single package

Create or edit a Brand for an Item.

Reprint Package Label

Automatically calculate the "Use By Date" for new packages.

Inventory: Recording a lab result and uploading COAs

Non-Inventory Items

Creating Trade Sample Packages and Trade Sample Adjustments

Inventory: Package Reference Fields

Flourish Costing

Inventory Audits

METRC - Retag Packages - Change the item of a package.

Flourish Inventory

Editing Items after Creating Packages

METRC - Discontinue package in METRC and Re-sync to Flourish

Set The Unit Weight for Packages of Items with UOM of 'Each'

Refreshing Inventory Count Details

Outbound - Return Rejected Items to Inventory

MMJ Used Package Attribute

Manage Packages waste

Managing Non-Cannabis Inventory

Creating Packages and Auto-Prompting Label Printing

Inherit Package Attributes

Inventory: Upload PDF To Record Lab Test Results

Refresh Inventory of Non-Cannabis Items

Inventory: Package Attributes

Package Harvests Data Management

How to Know When to Restock Your Inventory

Finished Goods Package Attribute

Metrc Retail ID Guide

Manufacturing

Manufacturing Module Overview

Manufacturing Work Orders with BOMs

Creating Bill of Materials for Handling Case Quantities

Manufacturing Waste Log

Creating a Bill of Materials - BOM

Start a New Manufacturing Run

Creating Inventory using Bill of Materials

Outbound

Outbound Overview

Outbound Invoice

Outbound orders Payment Status

Outbound Order Discounts and Charges

Creating New Outbound Shipments (Non-METRC)

Add, Edit and Delete Order Notes

Scan Packages to add Order Lines and Allocate Packages to Outbound Orders

Allocate Packages to Outbound Order

Sales Order Approval

Outbound Order Notes

Outbound Module Operational Overview

Invoice Date

Split Packages During Order Allocation

Display Unit Cost and Total Cost when allocating packages to an outbound order.

Creating New Outbound Orders

Configuration: Only Show Items with Available Quantity

Allocate Packages to an Outbound Order

Find Orders

Set a Default Distributor for your Outbound orders

Import Outbound Orders with a Spreadsheet

Change Facility - Move an Outbound Order between Flourish Facilities.

New York - Outbound - Manage Adult-Use Cannabis Products Tax

Printing Options on a Sales Order

Selling Cannabis Inventory by Lot

California Excise Tax Rate 2023 Update

How to update financial info for shipped orders

Packing List

Outbound Order Status Fields

Mark Sales orders as fully paid

Sales Order Payments

Retail / POS

AeroPay

POSaBIT

Customer Management

Adding a Physician

Creating a Customer Profile

Deleting a Customer

Merging Customer Profiles

Customer Preferred Name

Edit the credit available to customers

In-Store, Delivery, and Pickup Orders

Retail POS Printing and Reprinting Receipts

Creating a Retail Delivery Route

Retail POS Printing Customer Labels

Checking In a Customer

METRC Retail Delivery: Edit order after marking “Out For Delivery”

Create Retail Pick Up and Delivery Orders

Retail Order Statuses

Retail POS Refund a Purchase

Fulfilling a Retail Order

POS Item Scanning Rules

Retail POS Complete a Purchase

Retail POS Create an In-Store Purchase

Retail - POS - Split an order line into multiple lines of the same item.

Removing an Order from the POS

Retail POS - Refund a Manual Card Transaction

Retail POS - Refund a POSaBIT - Manual Transaction

Retail POS Quick Sale

Retail - Med and Rec purchases

Retail POS - Refund an AeroPay Transaction

Replace Customer - Change the Customer on a Retail Purchase

Retail - Cancel a Completed Purchase

Retail Purchase Limit Enforcement

Till and Vault Management

Creating a Retail Transfer

Creating a Sub-Vault

Performing Pay Ins and Pay Outs

Closing a Till

Counting a Vault

Opening a Till

Reconciling E-Payments

Creating Retail Reasons

Creating a Till

Integrations

MMUR

MMUR CureAPI v4 (Florida Only)

MMUR Caregiver Selection

Florida Retail - Automatic Dispensation to MMUR on Delivery Orders

MMUR / CureAPI v4 Medical Cannabis Aggregate Limit

Alpine IQ Integration

Discounts

Retail Discounts Overview

Creating a Retail Discount

Retail — Standard and Advanced Discounts

Retail Discounts — Customer Attributes

Retail Discounts — Order Attributes

Applying a Retail Discount

Common Retail Discounts

In Store Menu

Flourish Software In Store Menu

In Store Menu Eligibility: Items and Discounts

In-Store Menu Controls

Vector Payments

Vector Payments Configuration

Vector Payments - POS Check Out and Reporting

Troubleshooting Vector Payments Terminals Not Connecting

Spendr

Retail

Till Report

Recording a POSaBIT transaction

Retail - POS - Set default printers and print

Retail Pre-Orders, Backorders, and Replacement Orders

Adding Payment Terminals & Assigning to a Till

Retail - Customer State ID, Medical ID data and expiration

Retail - Mark a Completed Purchase as Cancelled

Point of Sale Cash Drawer Configuration

Retail - Show Tax Breakdown by Type on Retail Sales Receipt

Retail Facility Configuration

Credit Card Manual payments for Retail Point of Sale

Retail Metrc Sync Error "Package Cannot Be Sold Because it Doesn't Exist in The Current Facility"

Retail - Void a Transaction

Retail - Export the Customer Purchase History

BioTrack

BioTrack (Connecticut)

Connecticut BioTrack Inbound

Connecticut BioTrack Cultivation Guide

Connecticut BioTrack Manifest Requirements

Connecticut Manifesting in Flourish for BioTrack Clients

Connecticut BioTrack Inventory

Connecticut BioTrack Category Conversions

Connecticut BioTrack - Accepting Rejected Inventory

BioTrack (Florida)

Florida BioTrack Integration Overview

Florida BioTrack Limitations

Florida BioTrack User Management

Florida BioTrack Drivers and Vehicles

Florida BioTrack Inventory Categories and Mapping

Florida BioTrack Item MMUR Configuration

Florida BioTrack Propagation

Florida BioTrack Cultivation Management

Florida BioTrack Harvesting

Florida BioTrack Inventory Creation

Florida BioTrack Inventory Destruction

Florida BioTrack Inventory Adjustments

Florida BioTrack - Undo Out of Sync Package

Florida BioTrack Inventory Count

Florida BioTrack Initial Inventory During 90 Day Conversion Window

Florida BioTrack Delivery Devices

Florida BioTrack Facility Areas Creation

Florida BioTrack Lab Samples and COA Management

Florida BioTrack Manufacturing

Florida BioTrack: Report Ingredients During Manufacturing

Florida BioTrack Inbound Receiving and Transfers

Florida BioTrack Order Fulfillment and Shipping

Florida Biotrack Retail Returns, Restocks, and Voids

Florida BioTrack: Plant Additives

Florida BioTrack: Retail POS User Guide

Florida BioTrack: Retail Fulfillment User Guide

Florida BioTrack: Retail Delivery User Guide

External API

Flourish Webhooks

Securing your webhooks

Flourish Software External API Key Management

Generate or Reset External API key

Integrations

Apex Trading

BarTender™

Google Workspace

LeafLink

LeafLink Integration Overview

LeafLink Integration Setup

Flourish LeafLink Integration Setup DIY - Start here!

Before Setting Up LeafLink Integration

LeafLink Integration Setup and Activation

After Setting Up and Activating the LeafLink Integration

Set a default Sales Representative for a customer in Leaflink

Leaflink Category Mapping with Custom Categories

Sync Flourish to multiple Leaflink Companies and Brands

LeafLink - Sell by Batch

LeafLink Integration - Exclude facilities from inventory quantity sync

Set The Status of Leaflink Orders to Sync To Flourish Software.

Leaflink Brands and Product Lines

LeafLink Troubleshooting

Outfield

Ordo

POSaBIT POS

QuickBooks Online

What Version of QuickBooks Online is Supported?

Integration: QuickBooks Online

QuickBooks Online Sync Settings

Enable Shipping Charges in QuickBooks Online

Disconnect (Un-map) Items, Destinations and Vendors

Setting Inventory Start Date

Switch your QuickBooks Online Account to work with Categories

Enable Syncing of Outbound Orders to Quickbooks

Transition an Item from "Inventory" to "Non-Inventory" types in Flourish and QBO.

Quickbooks Online: Syncing Order Discounts

Send Flourish Data To QBO Sales Order Custom Fields

Zapier

Alpine IQ E-commerce

Seed Technology Integration

Export Data From Flourish To QuickBooks Desktop

CYBRA MarkMagic® Integration Setup

Flourish Software HubSpot App and Integration Guide

Flourish Analytics – Green Check Integration and Verified Reports

METRC

METRC CA Microbusinesses Location Functionality.

Step 1 - preparing for METRC CA Location Functionality for Microbusinesses.

Step 2 - preparing for METRC CA Location Functionality for Microbusinesses.

My Package is out of sync - Location Invalid

Step 3 - Locate your packages - METRC CA Location Functionality for Microbusinesses

Location Functionality for California Microbusinesses

New York Metrc

Item and Category Configuration for New York State Compliance

METRC - Create Immature Plant Batches

Receive the Metrc External Transfer (New York Integration Steps)

New York Metrc Item Category and Lab Testing Guidelines

How to Enter Beginning Inventory in Metrc – New York Guide

METRC Integration Overview

How to Find or Generate your METRC API Key

Sync cultivation Data from METRC

METRC -Handle Out Of Sync Package, Item, Plant, Harvest or Strain.

My item is out of sync - How to get it back in sync with METRC

METRC - Killing mature plants - additional details

METRC - Creating clones overview

METRC - Handling rejected outbound packages

2. Differences in METRC and non-METRC installations of Flourish Software

METRC MO, OH and MA - include or exclude the prefix in names of items synced from METRC.

METRC - Inbound a package and use it to create clones

Manage METRC Tags

Creating Outbound Shipments and METRC Transfers

METRC Item Brands

METRC - Undo Package - Remove a created package that is out of sync

METRC CA - Edit cultivation tax on Inbound Orders

Metrc - Create a Transfer Template

How to Resync a package

Sync an Item from METRC

Retry sync - a case of invalid tag

METRC "External Transfer" - bring cannabis items into the METRC ecosystem.

Flourish Metrc Processing Job Integration (Manufacturing Runs and Work Orders)

METRC – "Replace Tag" for Plants and Plant Batches

METRC - Get my plants back in sync

Import METRC Categories

Un-map Out of Sync Items

How to order your Metrc Tags

How Retail Returns Sync to METRC

METRC - Update your METRC API Key

Retry Sync after the issue was resolved

METRC - Rename a Harvest

Auto-assign tags to items created by METRC reverse sync

METRC - My Retail Order is Out Of Sync

METRC CA - Reducing Immature Plant Batches - additional details

METRC Harvest - Retry Harvest Sync

METRC - Out of Sync Strain

Find your NYS Metrc License Number and API Key

METRC Permissions

METRC - Mothers Plants and Groups

Retry Sync - Case of "User not Authorized"

The destination Facility cannot receive Packages with the SubmittedForTesting Lab Testing State.

Un-sync An Item From a METRC Facility - Delete a Mapping Record

My package is out of sync

METRC – Change Strain for Plants and Plant Batches

METRC - Get my clone batch back in sync

Release Notes

Previous Release Notes

2020.02.23 - Software Release 4.6.0

2020.03.23 - Software Release 4.8.0

2020.04.06 - Software Release 4.9.0

2020.04.20 Software Release 4.10.0

2020.04.13 - Software Release 4.9.2

2020.05.04 Software Release 4.11

2020.05.18 Software Release 4.12.0

2020.06.01 Software Release 4.13.0

2020.06.15 Software Release 4.14.0

2020.06.22 Software Release 4.14.1

2020.06.29 Software Release 4.15.0

2020.07.13 Software Release 4.16.0

2020.07.27 Software Release 4.17.0

2020.08.10 Software Release 4.18.0

2020.09.02 Software Release 4.19.0

2020.09.14 Software Release 4.20.0

2020.09.28 Software Release 4.21.0

2020.10.12 Software Release 4.22.0

2020.10.26 Software Release 4.23.0

2020.11.09 Software Release 4.24.0

2020.11.30 Software Release 4.25.0

2020.12.14 Software Release 4.26.0

2020.12.29 Software Release 4.26.1

2021.01.11 Software Release 4.28.0

2021.01.25 Software Release 4.29.0

2021.02.09 Software Release 4.30.0

2021.02.25 Software Release 4.31.0

2021.03.09 Software Release 4.32.0

2021.03.23 Software Release 4.33.0

2021.04.09 Software Release 4.34.0

2021.04.21 Software Release 4.35.0

2021.05.03 Software Release 4.36.0

2021.05.18 Software Release 4.37.0

2021.06.08 Software Release 4.38.0

2021.06.29 Software Release 4.39.0

2021.07.20 Software Release 4.40.0

2021.08.03 Software Release 4.41.0

2021.08.17 Software Release 4.42.0

2021.08.31 Software Release 4.43.0

2021.10.05 Software Release 4.45.0

2021.10.19 Software Release 4.46.0

2021.11.02 Software Release 4.47.0

2021.11.16 Software Release 4.48.0

2021.11.30 Software Release 4.49.0

2021.12.14 Software Release 4.50.0

2021.12.28 Software Release 4.51.0

2022.01.11 Software Release 4.52.0

2022.01.25 Software Release 4.53.0

2022.02.08 Software Release 4.54.0

2022.02.22 Software Release 4.55.0

2022.03.08 Software Release 4.56.0

2022.03.22 Software Release 4.57.0

2022.04.05 Software Release 4.58.0

2022.04.19 Software Release 4.59.0

2022.05.03 Software Release 4.60.0

2022.05.17 Software Release 4.61.0

2022.06.01 Software Release 4.62.0

2022.06.14 Software Release 4.63.0

2022.06.28 Software Release 4.64.0

2022.07.12 Software Release 4.65.0

2022.07.26 Software Release 4.66.0

2022.10.18 Software Release 4.72.0

2022.12.13 Software Release 4.76.0

2022.11.15 Software Release 4.74.0

2022.12.28 Software Release 4.77.0

2022.08.23 Software Release 4.68.0

2022.10.04 Software Release 4.71.0

2022.08.09 Software Release 4.67.0

2022.11.1 Software Release 4.73.0

2022.09.07 Software Release 4.69.0

2022.11.29 Software Release 4.75.0

2022.09.20 Software Release 4.70.0

2024.05.30 Software Release 4.106.0

2024.01.23 Software Release 4.100.0

2024.03.26 Software Release 4.103.0

2023.10.17 Software Release 4.96.0

2023.09.06 Software Release 4.94.0

2023.08.08 Software Release 4.92.0

2025.06.24 Software Release 4.119.0

2024.02.13 Software Release 4.101.0

2023.05.02 Software Release 4.85.0

2023.01.24 Software Release 4.79.0

2023.05.16 Software Release 4.86.0

2023.11.28 Software Release 4.98.0

2023.06.13 Software Release 4.88.0

2023.03.21 Software Release 4.83.0

2023.07.25 Software Release 4.91.0

2025.08.04 Software Release 4.120.0

2023.04.04 Software Release 4.84.0

2023.06.27 Software Release 4.89.0

2023.11.06 Software Release 4.97.0

2024.06.26 Software Release 4.107.0

2025.04.01 Software Release 4.114.1

2024.08.20 Software Release 4.109.2

2025.04.23 Software Release 4.116.0

2023.02.21 Software Release 4.81.0

2023.06.01 Software Release 4.87.0

2025.05.13 Software Release 4.117.0

2024.09.10 Software Release 4.111.0

2023.07.11 Software Release 4.90.0

2024.03.05 Software Release 4.102.0

2023.01.10 Software Release 4.78.0

2025.12.07 Release Notes

2023.12.17 Software Release 4.99.0

2025.03.11 Software Release 4.114.0

2024.11.20 Software Release 4.112.0

2023.03.07 Software Release 4.82.0

2024.05.07 Software Release 4.105.0

2025.09.16 Software Release 4.123.0

2025.10.07 Software Release 4.124.0

2023.09.26 Software Release 4.95.0

2025.11.18 Software Release 4.126.0

2025.08.26 Software Release 4.122.0

2023.08.22 Software Release 4.93.0

2023.02.07 Software Release 4.80.0

2025.06.03 Software Release 4.118.0

2024.04.16 Software Release 4.104.0

2025.10.29 Software Release 4.125.0

2026.01.27 Release Notes

Table of Contents

- All Categories

- BioTrack

- BioTrack (Florida)

- Florida BioTrack Inventory Creation

Florida BioTrack Inventory Creation

Florida BioTrack Inventory Conversion guide on how to sublot/split packages, convert inventory, change item, and use BOMs within the Inventory Module.

Convert inventory within Flourish's Inventory Module using the package action menu or inventory menu. Note, inventory conversion is also available within Flourish's Manufacturing Module.

There are several different types of inventory conversion. In general, inventory flows from a cultivation category to a lot product. Then it goes to one or more intermediate products until it reaches a final product category. Flower products skip any intermediate categories. Within each category users can split (sublot) and change item. Flourish handles the appropriate logic and filters selectors to enforce any BioTrack business rules. Refer to the guide on item category set-up for more details on configuring items.

Quick Reference: Florida BioTrack Conversion Matrix

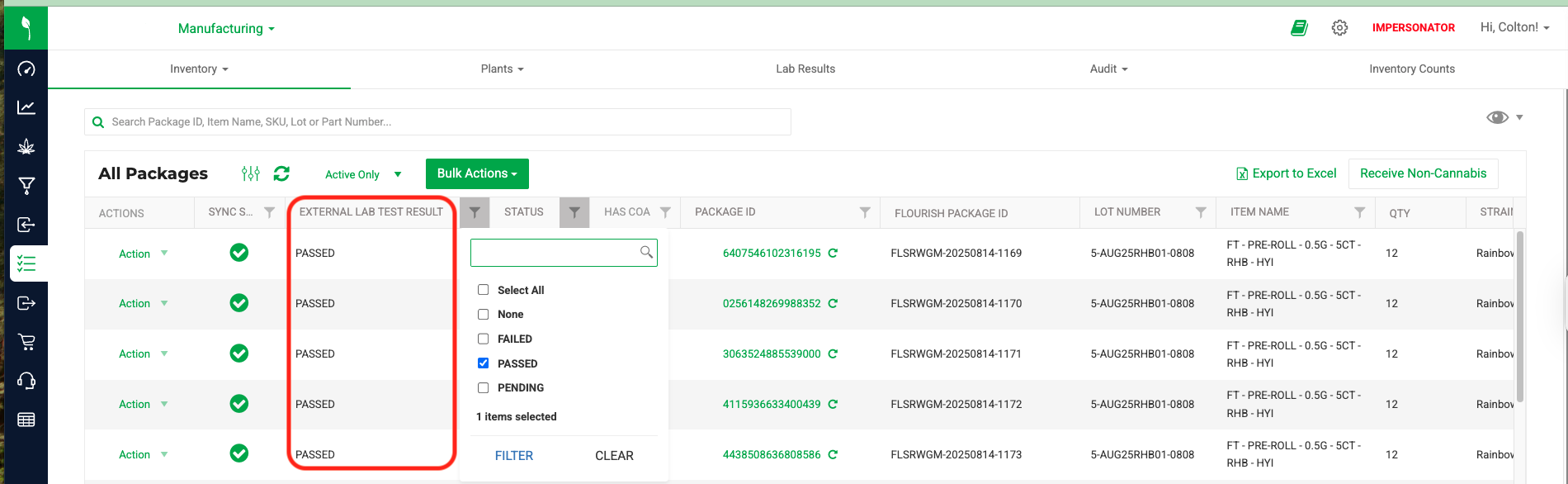

External Lab Test Result

The External Lab Test Result column in the Packages grid, located next to the Sync Status column by default, displays the BioTrack lab/QA status for each package. Values include PASSED, FAILED, PENDING, or Blank. You can adjust the column’s position in the grid settings and rename (alias) it to fit your workflow.

Important to know:

- Click the Refresh button

next to the Package ID to sync lab test results from BioTrack.

next to the Package ID to sync lab test results from BioTrack. - Ensure the source package has a PASSED External Lab Test Result before splitting it. If the source package’s result is Blank at the time of splitting, the descendants will also show Blank, even if the source package updates later.

- You can split packages with a PENDING lab result, and the descendants will inherit the lab result once it’s resolved.

- Keep cannabis products in PASSED status before transferring them to retail locations.If the products are not in PASSED status, the transfer to the retail location will fail.

Lot Product

When inventory is cured during harvest, it enters the inventory module as a cultivation inventory type item. Flourish uses the strain name and category to name this barcode. Example: "Blue Dream - Flower."

A user must first turn the inventory into a Lot Product to take it further. This is also where the user will assign the lot number. There are three types of lot products.

Flower Lot | This inventory typically starts as an untrimmed and unsorted flower. Use the sublot feature to split quantities from the starting barcode and rename the inventory appropriately. |

Kief Lot | Currently, Kief must come from an "Other Material" cultivation item. |

Other Material Lot | This is the BioTrack term for trim. |

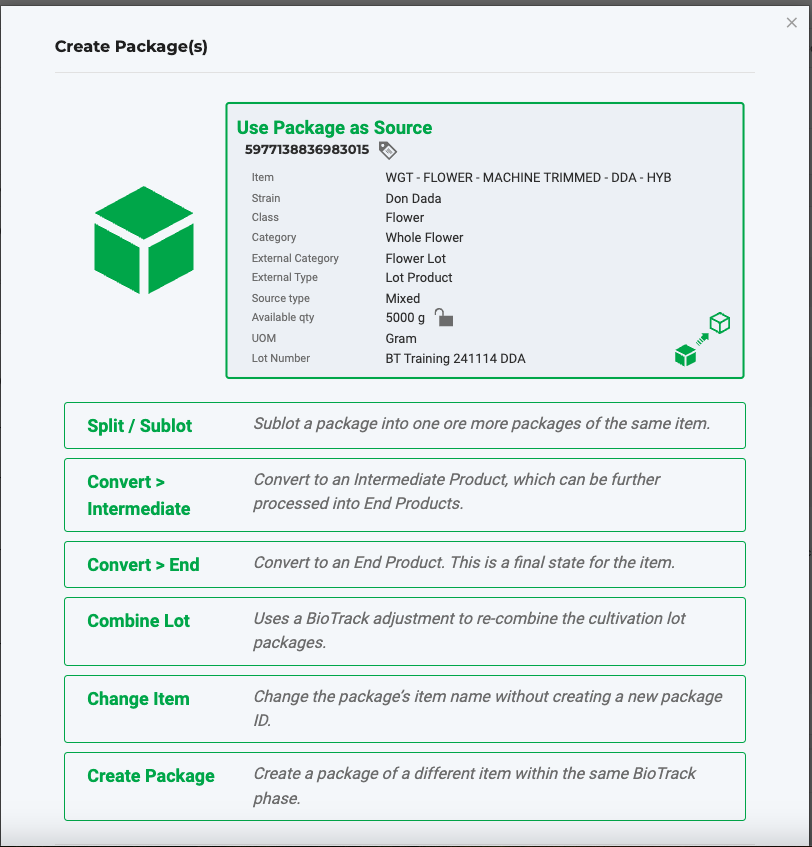

Create Package

To create inventory for existing packages and access the actions below:

- Go to Inventory

- Locate the package you need

- Click Action>Create package

- Flourish displays the available actions according to the item and the BioTrack business rules that apply to this item and category. Not all the action are available for every package.

Sublot (Split)

Use the Sublot function to split inventory into smaller quantities. "Sublot" is the BioTrack term for taking a certain amount of inventory out of one package and putting it into another.

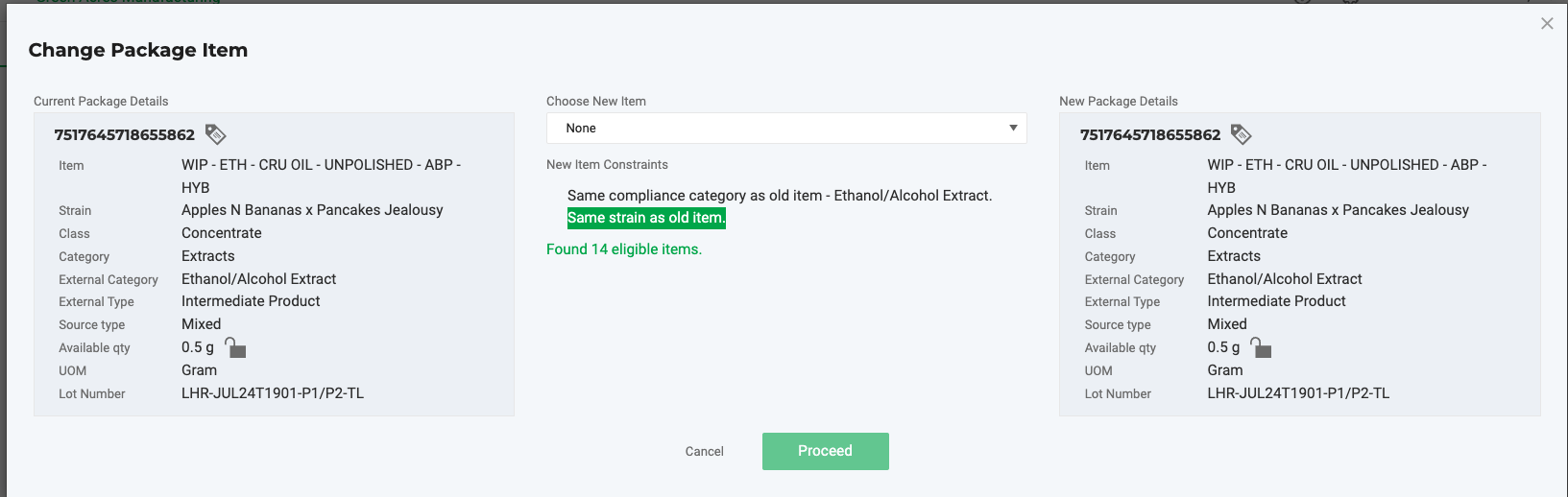

Change Item

BioTrack allows users to change the item name on a package. Use this function after harvest, in conjunction with Sub-lotting/Splitting, or at other times as is appropriate for the business process. Flourish recommends changing the barcode if the product changes form or stage, as this makes the history easier to report on.

New Item Constraints

- The new item must be in the same compliance category as the old item.

- The new item must be in the same strain as the old item.

Convert Inventory

Call the "Convert" function when changing categories.

A few important notes:

- The Florida BioTrack Conversion Matrix documents the business rules to consider when converting inventory. Flourish pre-filters the item selector accordingly.

- Users can convert inventory to an "intermediate" type and call subsequent conversions. However, once a product reaches a "final product" category users can only sublot and change item.

- The output quantity can be less than the input quantity.

- The output quantity can only be 1g larger than the input quantity.

Create Using Bill of Materials

It's important to configure the BOM correctly, considering the Florida BioTrack Conversion Matrix. Use the menu option in the Inventory Module to call the BOM and deduct non-cannabis inventory as the inventory changes form. Flourish recommends using the Manufacturing Module. when possible, to also document the process type and machine/workstation, to save the work in progress, and to have a clear history on manufacturing operations.

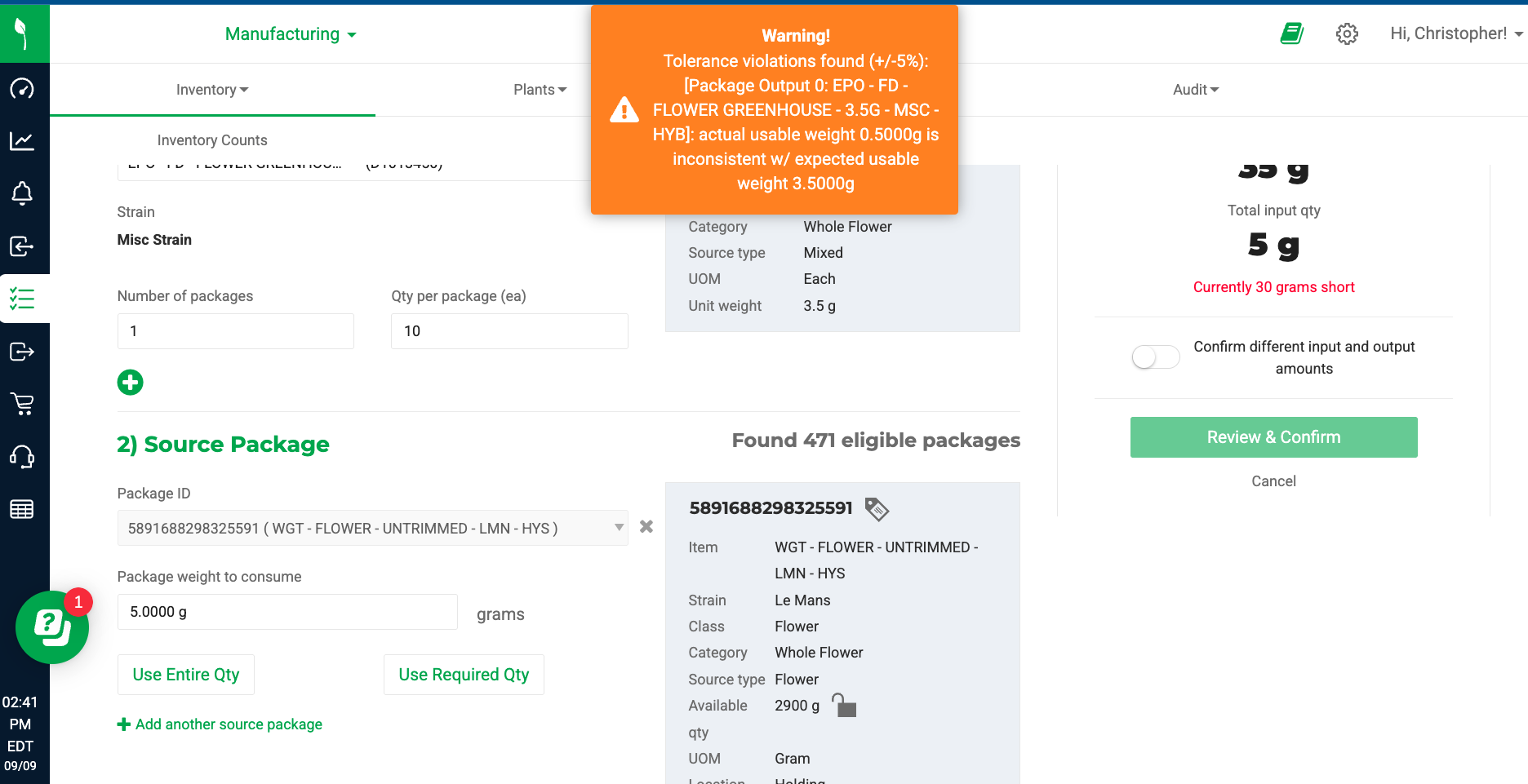

Usable Weight Validation

Why

Flourish Software now helps you create End Product packages with the correct usable weight. During package creation, the system checks the usable weight reported to BioTrack to catch errors early and prevent compliance issues.

How

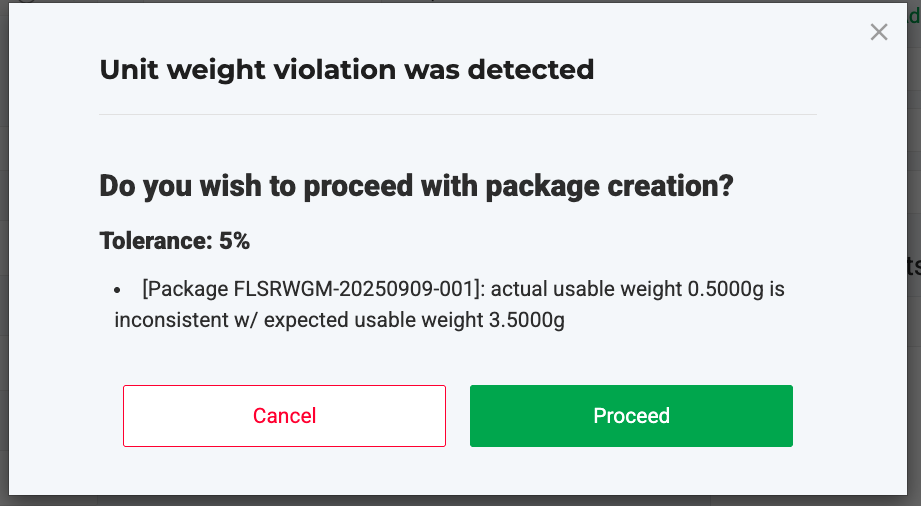

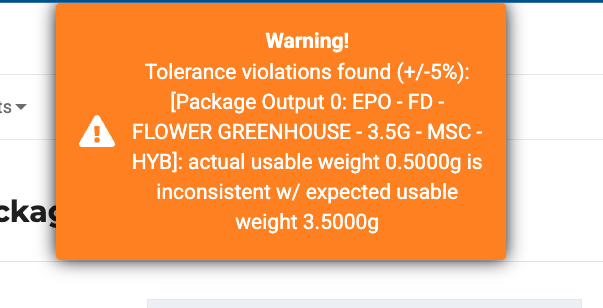

When creating packages of End Products in BioTrack Florida, Flourish now checks that the usable weight reported to BioTrack matches the unit weight of your output item. If there’s more than a 5% difference, you’ll see a warning before creation. You can adjust the weights or override to proceed, helping you catch errors early and ensure packages reflect the correct usable weight for compliance.

This validation applies across all package creation workflows:

- Package to Package

- Manufacturing Run

- Bill of Materials (BOM)

- Work Order

Examples of Validation messages

|

|

How did we do?

Florida BioTrack Harvesting

Florida BioTrack Inventory Destruction